What if a cyber-physical world — fueled by data — shortened production and manufacturing decisions to the time it takes to adjust a thermostat’s temperature? This just begins to describe Industry 4.0. According to a recent McKinsey article, Industry 4.0 “expects to deliver between $1.2 and $3.7 trillion in value.” Meanwhile, according to Riasat Noor, a writer at MIT Climate, technical capabilities “double every 18 months” where “already the current level of digitization is 54%.”

Industry 4.0, a revolutionary business model driving decentralized distribution and production with data, promises high expectations for companies. This up-and-coming model combines leading and emerging technologies through each business process, from product conception to the physical item or service reaching the customer.

Understanding the intricacies of Industry 4.0 can be tricky for many company leaders. Close to 70% of companies have initiated Industry 4.0 prototypes struggling to gain traction and “less than 30% of manufacturing companies are actively rolling out Industry 4.0 at scale.” This article will clarify Industry 4.0 by explaining why it is — and will continue to be — a major transformation.

Industry 4.0: A Change in the Business Mindset

Why talk about Industry 4.0 instead of advancements in Information Technology, Industry 3.0?

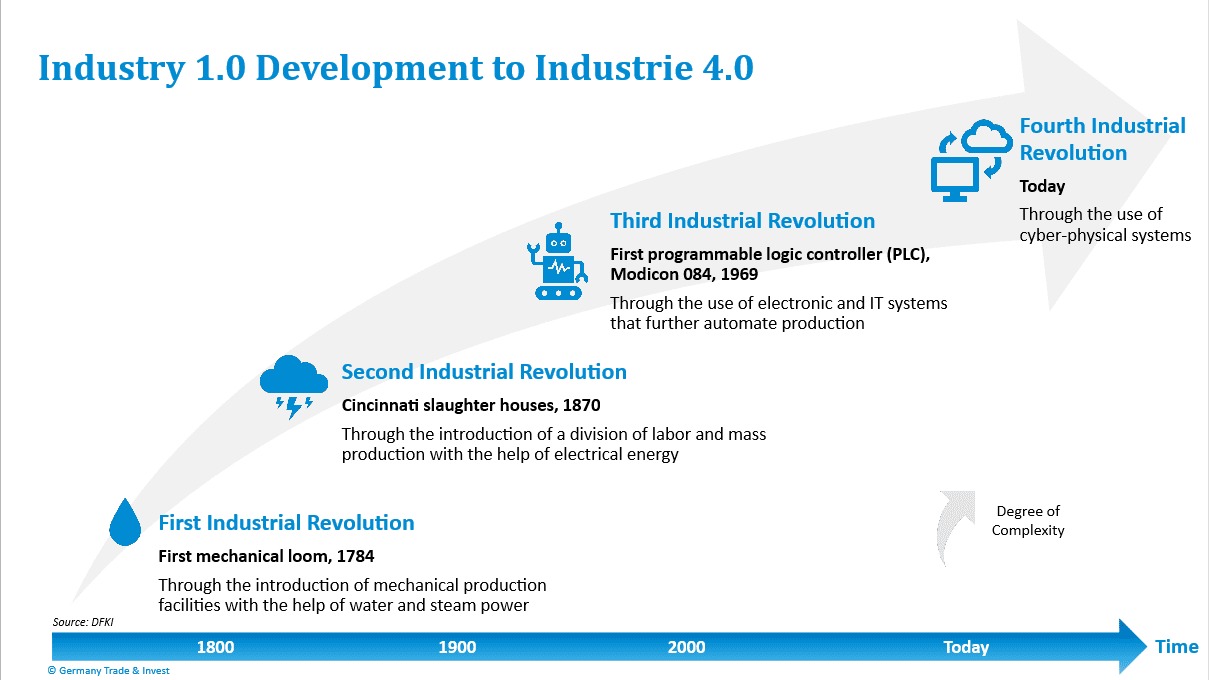

Each industrial revolution, with faster and more efficient results, greatly changes how people think of and do business. Companies are experiencing this type of radical shift today, as shown by Germany Trade & Invest (GTAI), the economic development agency of the Federal Republic of Germany.

The First Industrial Revolution occurred with engines powered by steam and water. Factories opened, transforming manufacturing that had been done on the homestead or farm. During Industry 2.0, electricity led to the rise of mass-produced goods and new devices such as the telephone and automobile. Industry 3.0 captured the use of information technology. Entire processes could be automated. The personal computer allowed people to take work home. Advances in biological technologies meant people lived longer. E-commerce and Amazon.com demonstrated a more efficient supply chain delivering goods at less cost.

Data drives this Fourth Industrial Revolution. Industry 4.0., also known as IIoT or “Smart Factories,” describes collective market responses to the enormous amount of data generated very quickly. The German government coined Industry 4.0 in 2003, as part of a new industrial policy in response to decentralized, autonomous, real-time manufacturing practices. Bernard Marr from Forbes describes this as interconnected computer networks that learn, make decisions, and communicate without the need for the type of human intervention required by manufacturing in the past. Data has and will continue to fuel this newest transformation, driving machine and human decisions.

How Data Fuels Industry 4.0

Companies have better access to data and processing capabilities. Sensors on the Internet of Things (IoT) means that data can be tracked in every step of product creation, manufacturing, and delivery. Through cloud computing, data can be stored, processed, and queried from almost anywhere. Smartphones allow managers to view this information from the factory floor. Machine learning intelligently automates tasks, such as identifying and correcting a product flaw in mid-production. Digital twins — prototypes of products and services — highlight both process efficiencies and potential points of failure before a company spends too much time and money on it. Data assets form the core optimizing processes, quality, and transaction flow, ideally on the fly.

These newer technical abilities have contributed to rising consumer requirements for on-demand information from one place. Users want to see all the information and know what actions to take immediately. Consider the Nest thermostat. Owners can raise or lower the heat from work or in the car. Should someone wish to optimize their utility bill, they can view usage history and adjust. Even better, the device learns thermostat preferences and can turn down the temperature when the user is not at home. This functionality makes up just the beginning of Industry 4.0.

Picture this scenario: Both the customer and the utility company, due to advances in connectivity, see the same thermostat history, say through data virtualization. The utility company and the consumer, with some augmented analytics, see patterns in reduced energy usage and develop data models. The utility company proceeds to develop machine learning algorithms that read these data models and automatically reduces the consumer’s heating bill. Software developers, analysts, customer representatives, and quality assurance workers check on these programming for any anomalies and to verify Data Quality and application. Payment could very well be determined, be adjusted, and happen in real-time, as the heat flows through the house. The money would be taken out of a consumer’s account every day to pay for heat, instead of monthly.

Think about troubleshooting heating problems by the week, or day, or hour. Since both the consumer and the utility have access to the same thermostat history, a customer could question the information quality or the analysis by the utility company within minutes. Say the company connects to the thermostat and, through a combination of human, automated and machine learning interventions, using data, finds a worn part. The thermostat compensates the temperature calculations, fixing the problem, without needing to send a technician or representative. Algorithms automatically adjust customer’s bill. Meanwhile, factories making Nest thermostats and distributers, located around the world, get this information and correct the thermostat flaw on the fly. Quite a change in pace.

The Nest thermostat example shows how the start of Industry 4.0 has already changed the energy marketplace and has given a rough direction of where the energy business may be headed, with faster and more efficient payments, supply, demand, and troubleshooting. Yes, details about the Industry 4.0 path remain unknown; however, leaders can see this means major transformation across business strategy, technology solutions, and organizational culture, in addition to Data Strategy. All of this fueled by shared business and consumer data.

Challenges Ahead

How fast Industry 4.0 comes to fruition depends on how quickly companies meet data challenges. Companies need a solid data foundation across the enterprise and the means to build and maintain such a structure.

Bettina Tratz-Ryan, a Research Vice President at Gartner, commented that CIOs in Germany, Austria, and Switzerland (the DACH region) lack IT and business resources to shift into Industry 4.0. These problems intensify, said Gary Bloom from Forbes when “companies have a mishmash of databases and software systems from acquisitions.”

Cybersecurity, related to having good data connections and foundation, will also prove to be a major obstacle toward adopting Industry 4.0. For starters, Data Quality is called into question when a hacker has injected bad data into the system. Second, data can be non-compliant due to unintended leakage, vulnerabilities, and unauthorized access. Finally, Industry 4.0 relies on less human intervention and more automated processing by intelligent machines. But machines can be tricked into storing, processing, and or using bad data sets easier than humans can be. Without attention to cybersecurity risks, these flaws could turn up later in the manufacture and distribution process, reducing company revenue and reputation.

In addition to cybersecurity, people and work cultures will become key to Industry 4.0 progress. According to Professor John Van Maanen at the MIT Sloan School, Industry 4.0 transformation relies on 20 percent technology and 80 percent on how people work together.

The World Economic Forum foresees more automated replacement for routine and repetitive tasks. For example, machines can handle typical invoice processing and bill pay. Companies will need workers with new analytical and mathematical capabilities to watch for digital patterns and anomalies. Data enablement will become very important in helping workers adapt to Industry 4.0 “through data literacy, user-friendly technology, and an enterprise-wide data culture.” Firms will need to resolve worker ownership and accountably around enterprise data, especially where employees have competing priorities.

Conclusion

Data will continue to drive Industry 4.0 into a new business mindset. This transformation is in progress and will continue to grow. Forming a strong data foundation with a firm Data Strategy will be critical in driving Industry 4.0 and well worth the time, as a CEMEX case study shows. In the meantime, start small with Industry 4.0, advises Ran Poliakine in Forbes, and then scale up from there. Industry 4.0 will not happen overnight, but companies can lay the groundwork and be ready for when it accelerates.

Image used under license from Shutterstock.com